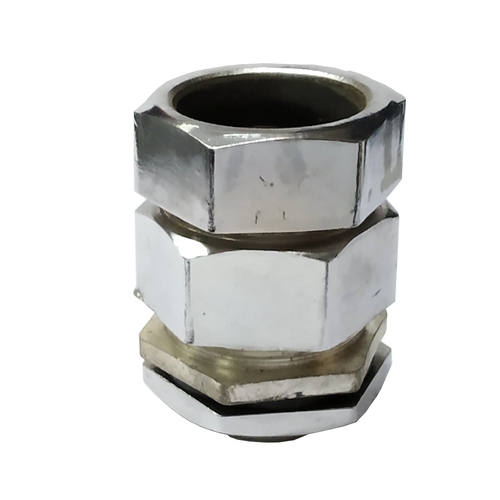

CW Cable Gland

Price 50-400 INR/ Piece

CW Cable Gland Specification

- Insulation

- Not directly applicable (provided by used cable)

- Locking Type

- Hex locknut/fitting nut (mechanical clamping)

- Armored Material

- Steel wire/strip (SWB/SWA, gland is compatible)

- Conductor Shape

- Round (assumed as typical for armoured cable)

- Operating Temperature

- -20C to +80C

- Dielectiric Strength

- Not Applicable (dielectric property pertains to cable, not gland)

- Install Type

- Threaded/gland compression fitting

- Usage & Applications

- Electrical installation, wiring termination, outdoor and indoor use in industrial, commercial sectors

- Features

- Weatherproof, corrosion resistance, suitable for armoured cable termination, earth continuity ensured via armour clamp

- Weight

- Varies as per gland size

- Rated Temperature

- -20C to +80C

- Number of Conductor

- Cable dependent; gland suitable for single/multi core armoured cables

- Conductor Type

- Stranded/Solid (cable-specific, gland compatible with both)

- Core Material

- Copper/Aluminium (as in cable used)

- Core Number

- As per cable used

- Tensile Strength

- High mechanical strength

- Cable Type

- Armoured Cable (SWA, STA, AWA, strip or wire armouring)

- Diameter

- Varies by cable size (16mm to 90mm)

- Product Type

- CW Cable Gland

- Length

- Customizable as per cable size/application

- Voltage

- Up to 1000V

- Insulation Material

- PVC (used with the cable)

- Application

- Outdoor and indoor armoured cable connections, power distribution, control panels, junction boxes

- Conductor Material

- Copper/Aluminium (refers to the cable, not the gland)

- Jacket Material

- Not Applicable (metallic gland construction)

- Storage Temperature

- -20C to +80C

- Connector Color

- Metallic (natural brass finish or nickel-plated)

- Shield Material

- Not Applicable (focus on earth continuity via armour clamp)

- Jacket Color

- Not Applicable (metallic)

- Dimension (L*W*H)

- Varies by gland size (per metric/British Standard)

- Material

- High grade Brass (nickel plated or plain)

- Color

- Brass/nickel plated silver

- Size

- Available from 16mm to 90mm metric, and matching imperial/British sizes

CW Cable Gland Trade Information

- Minimum Order Quantity

- 500-1000 Pieces

- Supply Ability

- 1000 Pieces Per Day

- Delivery Time

- 20-45 Days

About CW Cable Gland

We are occupied in manufacturing, exporting and supplying the best quality Cw Cable Gland. The offered gland is manufactured under the stern observation of our dedicated professionals using optimum quality raw materials with the aid of latest techniques. This gland is widely used as a sealing gland for electrical power, instrumentation, data and telecommunications cables. In addition to this, the provided Cw Cable Gland can be purchased from us in several sizes at economical prices.

Superior Ingress Protection

Engineered to withstand harsh weather and dust exposure, CW Cable Glands offer ingress protection of IP66/IP67. This ensures reliable shielding against water and dust, safeguarding your cable connections in both outdoor and challenging industrial settings. Suitable washers and seals further enhance their protection, providing operational integrity across a wide temperature range.

Flexible Design for Diverse Installations

CW Cable Glands accommodate various thread types, including Metric (ISO), BSP, and PG, and suit a broad spectrum of cable diameters and types. Their through-type entry makes them ideal for round, armoured cables, with the choice of tough neoprene or EPDM seals for additional security. The customizable length and robust locking mechanism provide added installation flexibility.

Earth Continuity & Safety Assurance

The featured armour cone and clamp assure effective earth continuity from the cables armour directly to the gland body, making these glands suitable for terminations in critical power distribution, control panels, and junction boxes. High mechanical strength and durable materials offer longevity in industrial and commercial applications.

FAQs of CW Cable Gland:

Q: How do you install a CW Cable Gland on an armoured cable?

A: To install, strip your armoured cable to expose the appropriate length of armour and conductor. Slide components onto the cable according to the gland kit instructions, ensuring the armour cone and clamp grip the steel wire or strip effectively. Tighten the hex locknut using a compatible spanner or wrench to secure the glands body and establish solid earth continuity.Q: What types of cables can be terminated with a CW Cable Gland?

A: CW Cable Glands are designed specifically for round armoured cables such as SWA (steel wire armoured), STA, AWA, and cables with strip or wire armouring. They are compatible with both single and multicore cables with either copper or aluminium conductors in stranded or solid configurations.Q: When should a weatherproof cable gland like this be used?

A: Use CW Cable Glands when you require robust weatherproofing and environmental protection for your cable terminations, such as in outdoor electrical installations, industrial power networks, control panels, and junction boxes, where dust, water ingress, and earth continuity are concerns.Q: Where can CW Cable Glands be applied?

A: These glands are suitable for both indoor and outdoor environments, particularly in industrial and commercial electrical installations across power distribution and control systems. They cater to applications requiring reliable armour clamping and earth continuity, including service entries, distribution panels, and industrial machinery.Q: What benefit does the armour clamp mechanism provide?

A: The CW Cable Glands armour clamp mechanism securely grips the cables armouring, ensuring a dependable mechanical and electrical connection. This provides effective strain relief, maintains earth continuity, and improves safety in installations exposed to vibration or mechanical stress.Q: Which tools are compatible for installing these glands?

A: You can install CW Cable Glands using standard spanners or wrenches sized according to the gland size. No specialized tools are required, making installation straightforward for electricians and technicians.Q: What are the advantages of the nickel-plated finish over natural brass?

A: A nickel-plated finish enhances corrosion resistance, making the gland better suited for aggressive or highly corrosive environments. Natural brass is ideal for general use, while nickel plating provides added protection where environmental conditions demand it.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Brass Cable Gland Category

Marine Cable Glands

Price 50-400 INR / Piece

Minimum Order Quantity : 5001000 Pieces

Tensile Strength : High tensile strength for marine installations

Cable Type : Armored, Unarmored, Flexible, Marine Cables

Diameter : Fits cable diameters 6mm 63mm

Connector Color : Silver

PG Cable Glands

Price 50-400 INR / Piece

Minimum Order Quantity : 5001000 Pieces

Tensile Strength : Approx. 650MPa

Cable Type : Round Cable, Flexible Cable

Diameter : Clamping range varies: PG7 (36.5mm), PG9 (48mm), PG11 (510mm), PG13.5 (612mm), PG16 (1014mm), PG21 (1318mm), PG29 (1825mm), PG36 (2232mm), PG42 (3238mm).

Connector Color : Grey/Black

Aluminum Cable Gland

Price 50-400 INR / Piece

Minimum Order Quantity : 5001000 Pieces

Tensile Strength : Good mechanical resistance (varies by size)

Cable Type : Suitable for armored and unarmored cables

Diameter : Cable range typically from 4mm to 55mm depending on model

Connector Color : Natural aluminum finish

BW2 Cable Glands

Price 100 INR / Piece

Minimum Order Quantity : 500 Pieces

Tensile Strength : High

Cable Type : Armoured Cable

Diameter : As per selected size

Connector Color : Metallic Silver

|

VISHNU BRASS INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry