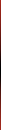

Aluminum Cable Gland

Price 50-400 INR/ Piece

Aluminum Cable Gland Specification

- Diameter

- Cable range typically from 4mm to 55mm depending on model

- Features

- Corrosion resistant, High strength, Durable, Easy installation

- Install Type

- Threaded coupling, panel mount

- Rated Temperature

- -20C to 80C

- Armored Material

- Aluminum body, compatible with armored cables

- Usage & Applications

- Power distribution, electrical panels, motors, control equipment

- Locking Type

- Locknut or compression type

- Insulation

- Non-insulated type

- Tensile Strength

- Good mechanical resistance (varies by size)

- Cable Type

- Suitable for armored and unarmored cables

- Operating Temperature

- -20C to 80C

- Weight

- Varies by size

- Product Type

- Aluminum Cable Gland

- Length

- Customizable as per cable size

- Voltage

- Up to 1000V

- Insulation Material

- Standard non-insulated, suitable for outdoor/indoor use

- Application

- Securing and sealing cables entering enclosures, electrical panels, machines

- Conductor Material

- Not applicable (suitable for any type)

- Jacket Material

- No outer jacket (body is bare aluminum)

- Storage Temperature

- -20C to 80C

- Connector Color

- Natural aluminum finish

- Jacket Color

- Natural

- Dimension (L*W*H)

- Depends on cable gland size, typically ranging from M16 to M63

- Color

- Silver/Natural

- Material

- Aluminum alloy

- Size

- M16, M20, M25, M32, M40, M50, M63 or as specified

Aluminum Cable Gland Trade Information

- Minimum Order Quantity

- 500-1000 Pieces

- Supply Ability

- 1000 Pieces Per Day

- Delivery Time

- 20-45 Days

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Export Market(s)

- Australia, Middle East, Africa, Asia, Eastern Europe, North America

- Main Domestic Market

- All India

About Aluminum Cable Gland

The offered Aluminum Cable Gland is widely used in electrical systems to make tight and reliable connecting ends for better fitting of the wires within a power system. It is designed and developed by our skilled professionals by using latest machining technologies to provide higher dimensional accuracy for easy installation. This component part is coated with a polished coating to prevent damages due to rust and corrosion for longer service life. Buyers can get this component art from us in large quantities at a low price.Superior Ingress Protection and Durability

Rated up to IP68 depending on installation, this aluminum cable gland excels at preventing water, dust, and foreign particles from entering enclosures. The anti-oxidized, non-flammable aluminum alloy body provides enduring resistance to harsh environmental factors, making it suitable for both outdoor and indoor installations. Each unit delivers high mechanical strength and is designed for frequent exposure to challenging conditions.

Versatile Application and Installation

With support for cable diameters ranging from 4mm to 55mm and multiple thread types (Metric, PG, NPT), these glands fit a broad spectrum of wiring requirements. They are compatible with both armored and unarmored cables and include essential mounting accessories such as locknuts and washers, streamlining installation on panels and machinery. The glands customizable length ensures precise cable management for every setup.

Reliable Cable Sealing and Retention

Incorporating high-quality silicone or neoprene seal inserts, these cable glands offer excellent sealing and strain relief, effectively securing cables and mitigating mechanical stress. The design ensures that openings stay tightly sealed even with frequent movement or temperature fluctuations, maintaining safe and efficient electrical connections while extending service life.

FAQs of Aluminum Cable Gland:

Q: How does the aluminum cable gland achieve a high ingress protection (IP66IP68) rating?

A: The cable gland uses precision engineering, high-quality sealing inserts (typically silicone or neoprene), and robust aluminum construction. When properly installed, these features prevent dust and water from entering electrical enclosures, achieving up to IP68 protection depending on the installation and model chosen.Q: What cable sizes and thread types are compatible with these glands?

A: These glands accommodate cables from 4mm to 55mm in diameter and are available with Metric, PG, or NPT threads. Customizable lengths and various sizes (M16 to M63) allow integration into a wide range of electrical panels, machines, or distribution systems.Q: When should I choose an aluminum cable gland over other materials?

A: Aluminum cable glands are ideal when you require high mechanical strength, corrosion resistance, and non-flammable properties, especially in outdoor or demanding industrial environments. They are suitable for both armored and unarmored cables operating in a temperature range of -20C to 80C.Q: Where are these aluminum cable glands typically used?

A: They are commonly installed in power distribution units, motor control centers, electrical panels, industrial machinery, and any environment where cables enter sealed enclosures. These glands are engineered for both indoor and outdoor applications due to their weather-resistant properties.Q: What is the process for installing an aluminum cable gland?

A: Begin by selecting the appropriate gland size and thread type for your cable and panel. Insert the cable through the gland, position the sealing insert, and secure the assembly using the included locknut and washer. This ensures a tight fit, proper sealing, and mechanical strain relief for the cable.Q: How does the gland ensure mechanical safety and strain relief for cables?

A: The aluminum gland provides high cable retention, holding the cable securely in place and preventing movement that could damage conductors or connections. The seal insert adds further strain relief, protecting cables from pull and vibration.Q: What are the benefits of using bare aluminum cable glands with anti-oxidized finishes?

A: A bare, anti-oxidized aluminum finish delivers robust corrosion resistance, a natural silver appearance, and ensures lasting performance even in harsh industrial or outdoor environments. This surface treatment also minimizes maintenance and guarantees long-term reliability for electrical installations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Brass Cable Gland Category

Marine Cable Glands

Price 50-400 INR / Piece

Minimum Order Quantity : 5001000 Pieces

Application : Other, Marine cable sealing, Shipboards, Offshore platforms

Product Type : Marine Cable Gland

Jacket Material : Other, Rubber / Stainless Steel / Nickelplated Brass

Locking Type : Threaded / Compression fitting

PG Cable Glands

Price 50-400 INR / Piece

Minimum Order Quantity : 5001000 Pieces

Application : Other, Electrical control boxes, junction boxes, machines, outdoor/indoor cable installations.

Product Type : PG Cable Gland

Jacket Material : Other, Not Applicable (Used with external cable).

Locking Type : Threaded Nut Lock

CW Cable Gland

Price 50-400 INR / Piece

Minimum Order Quantity : 5001000 Pieces

Application : Other, Outdoor and indoor armoured cable connections, power distribution, control panels, junction boxes

Product Type : CW Cable Gland

Jacket Material : Other, Not Applicable (metallic gland construction)

Locking Type : Hex locknut/fitting nut (mechanical clamping)

A1 A2 Cable Gland

Price 50-400 INR / Piece

Minimum Order Quantity : 5001000 Pieces

Application : Other, Cable termination for unarmoured cables in electrical installations

Product Type : A1 A2 Cable Gland

Jacket Material : Other, Brass with nickel plating

Locking Type : Hexagonal lock nut

|

VISHNU BRASS INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry